Central heating and cooling in buildings:

Production and heat transfer (heating) or cooling (cooling energy) in central buildings of buildings by Warm Or cool water in a central source (for example, a home engine) and transfer It is transmitted through reciprocating pipelines (circulating) into radiators or fans of any individual unit of construction. In hot water systems, the temperature increases with gas and in the central refrigeration systems, depending on the type of system, the source of the refrigerant can be electricity or gas. ;

The central heating and cooling systems of the buildings have higher quality meanings due to their high efficiency and long life and low maintenance and lowering costs compared to the systems initially separated, such as heating and split systems, but increasing the price of energy carriers and the lack of separation Energy consumption in the central systems has led the public to pay attention to the separate heating and cooling systems and the margin of central systems.

The method of separating energy consumption in central heating and cooling systems:

Energy meter (heat and flow meter) with energy dissipation, building units and consequently the separation of energy costs of residential buildings are considered today as one of the most important prerequisites for central heating and cooling systems, because it is characterized by the following performance Differences in the cost of energy carriers (gasses) will be greatly reduced.

Energy meter components (temperature and humidity) and how it works:

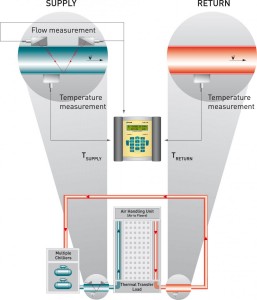

Energy meter with the purpose of measuring the energy consumption of each building unit (including the amount of use of radiators, fan coils, floor monitoring systems, ventilation and conditioning systems, etc.) consists of three separate sections:

۱٫ A pair of submerged resistance temperature sensors

۲-Flow Meter

۳٫ Calculator and display

-

The two temperature sensors are tracked down the water flow through the water-carriers of one unit, the difference in the water temperature of the inlet and outlet in which the building unit is created.

-

– Simultaneously, by measuring the temperature, the flow rate of water passing through the meter of the flowmeter is measured on the pipe or the return of water from the unit.

-

The numbers of temperature and discharge parameters are transmitted to the energy meter calculation.

-

Flow rate difference in water flow passing through the pipe. In a fixed thermal coefficient for water, the amount of energy consumed per unit (in jules or kilocalories) by standard data transfer protocols ( M-bus or Wm-bus ) according to the EN1434 and MID (the most important standard of measurement equipment in the world) to the central system And data aggregation transmitted and energy data consumed by all construction units in the data center are stored.

- In the end, these numerical parameters are transferred to a Billing software, and after calculating, the energy bills are converted to each building unit and exported through the printer.

Energy meters and their constituent equipment:

-

In the standard definitions of the measurement systems (<= span dir = "LTR"> MID, EN1434 ), meters are generated according to the type of equipment in two types of compact (single piece) or split (separate) , The energy of the meter’s meters up to 2.5 QP cubic meters per hour and in split models, usually from 3.5 The cubic meter is produced per hour to the top.

- Flowmeter

- Flow Meter The use of energy in a meter can be either in turbine (mechanical) or in ultrasonic.

- Type of flow meter used according to installation position, system type Heating and cooling, and so on.

- In turbine flowmeters, water debugging is measured by mechanical blades in the path, while in ultrasonic flowmeters, the audio cinemas sent from ultrasonic transducers counteract the fluid direction, calculates the water discharge.

- One of the most important advantages of ultrasonic flowmeters is the low pressure drop in the waterway and, in contrast, long-term calibration is one of the benefits of turbine flowmeters.

- One of the most important advantages of ultrasonic flowmeters is the low pressure drop in the waterway, and, on the other hand, long-term calibration is one of the benefits of turbine flowmeters.

- temperature sensor, thermometer:

- Temperature sensors used in all types of energy meters are submerged resistance sensor types and are mainly from the range of sensors

PT1000_PT500_PT100 ;.

- The temperature sensors used in the energy meters are available as cables, in the form of two-wire and four-sided.

- Flowmeter

- In the end, these numerical parameters are transferred to a Billing software, and after calculating, the energy bills are converted to each building unit and exported through the printer.